ABOUT COREXTRUSION

Created in 2016 in the Lyon region of France, Corextrusion Group is an R & D platform developing innovative 3D filaments meeting technical needs, in order to increase the performance of additive manufacturing by means of melted filament deposit. Corextrusion Group has developed a wide variety of materials for Companies wishing to produce, with 3D technology, small batches of parts, with mechanical characteristics or surface finishes similar to machined or inject moulded parts, without needing expensive tools, and in a fraction of the time.

This technology also makes it possible to produce parts that cannot be injection moulded. Our mission is to extrude technically advanced filaments which will allow you to produce 3D printed parts with your specifications. Our know-how and expertise in the field of extrusion has enabled us to develop a large number of amorphous, semi-crystalline, charged and uncharged materials to name a few. From extrusion to characterisation: All our filaments are printed, tested and characterised according to ISO standards used for injection (ISO527-ISO178-ISO179).

Tests we perform include tensile strength, elasticity, compression, shock and flexibility.

We have developed a comprehensive range of 3D filaments, under the “Tag in 3D™” brand.

TAG in 3D ™ filaments have been developed to achieve performance as well as ease of printing.

BREVETS DÉPOSÉS DE COREXTRUSION GROUP

Coextrusion exclusive

des filaments 3DTechnique de coextrusion exclusive

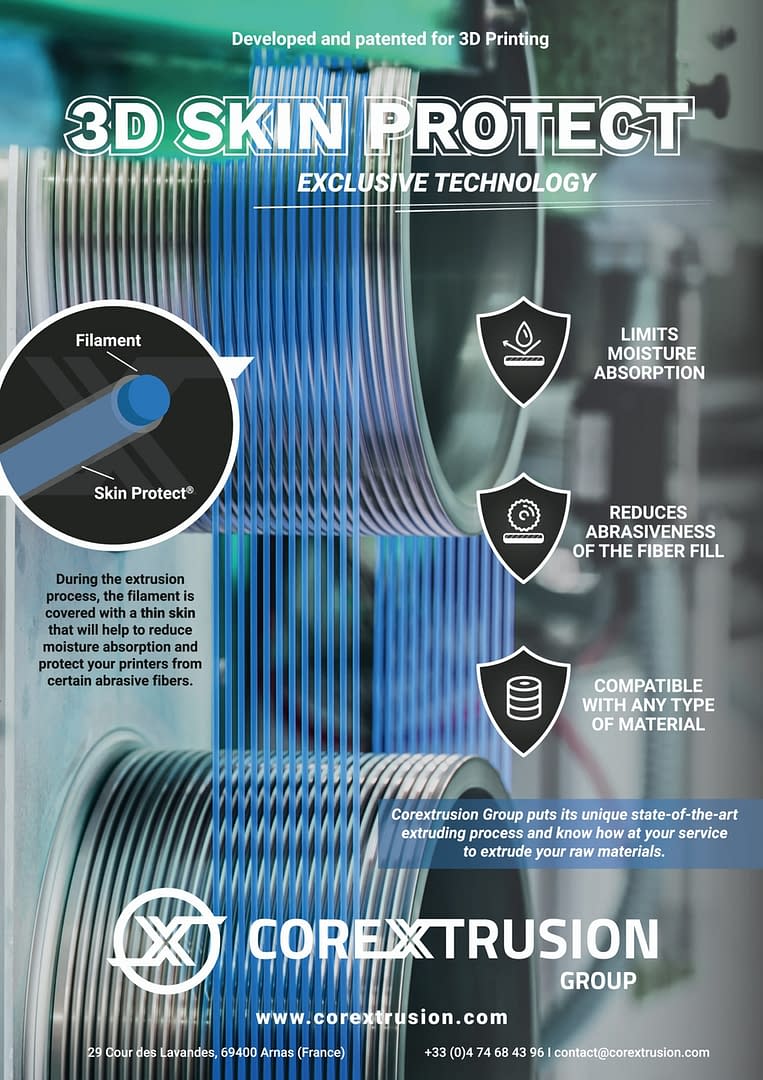

Corextrusion Group innove du côté des filaments 3D avec une technique de coextrusion exclusive. Cette technologie permet d’enrober un filament d’une fine peau pouvant avoir diverses fonctionnalités :

- elle limite la reprise d’humidité,

- elle protège vos imprimantes de certaines fibres abrasives,

- elle est compatible avec tout type de matières.

De nouvelles fonctionnalités vont bientôt voir le jour.

3D Skin Protect

Technique 3D Skin Protect

Cette peau permet d’imprimer tout type de matières en préservant la bonne marche de vos imprimantes 3D.

Imprimer des matières chargées en bronze ou en fibre de verre par exemple n’aura jamais été aussi facile grâce à cette technologie.

N’hésitez pas à nous faire parvenir vos cahiers des charges, et nous pourrons étudier la faisabilité de vos projets via cette technologie.

TAG in 3D filaments are produced with specially selected, high grade raw materials. They are perfectly suited for use in standard applications, but also in higher performance applications requiring more technically advanced raw materials, with highly consistent charge percentages, batch after batch.

TAG in 3D is in complete control of the production chain, from selecting the best raw materials, to mastering a unique extrusion and spool winding process (we inject mould our spools in-house), to packaging and logistics.

TAG in 3D is always on the move with continuous research in development and innovation for 3D printing.